Shock-Resistant Electric Contact Pressure Gauge

Application

The shock-resistant electric contact pressure gauge has excellent performances such as pulsation resistance, impact resistance, and vibration resistance. It is widely used in petroleum, chemical, chemical fiber, metallurgy, power stations and other industries, to measure the pressure of various fluid media in the process that require pulsation, impact or vibration resistance. Equipped with an electric contact device, this pressure gauge can be used for on-site indication and control the circuit C contact switch of the pressure control system.

Thereby achieving remote transmission and automatic control. When the pressure reaches a predetermined value, the control circuit can be turned on or off to achieve the purpose of automatic control. The shock-resistant structure of this pressure gauge can effectively suppress the jitter of the pointer, protect the contacts, make the indication clear, and the electrical signal switching reliable and stable.

Features

1. One contact device is a magnetically assisted gold-plated contact contact, which is surface contact, reliable in contact, and resistant to ablation.

2. Another contact device is reed switch contact, which can transmit signals well under low voltage (24V, 12V) without arcing phenomena. It has fast response speed and long service life. Its advantage is that the contact switch is isolated from the atmosphere, and there is noble gas or vacuum state in the tube, which can reduce the oxidation and carbonization of the contact. The sealed design can prevent external steam and dust impurities from corroding the contact. The reed switch contact enables the electric contact pressure gauge to be used in low- voltage systems, which makes the low voltage system intelligent.

Parameters

Diameter: φ100mm, φ150mm

Accuracy: 1. 6%

Working Pressure:

- Steady: 3/4 X full scale value

- Fluctuating: 2/3 X full scale value

- Short Time: Full scale value

Maximum power: 50VA, 10VA (Reed switch contact)

Working voltage: AC220V | AC380V I DC24V

Control Method: Upper and lower limits

Protection: IP65

Connection Thread: M20x1.5, PF(PT, NPT)1/2, etc.

Damping Liquid: Methyl silicone oil

Elastic element: Qsn8-0.3 brass I SUS304 I SUS316L

Connection Material: HPb59-1 brass I SUS304 I SUS316L

Movement: Brass I SUS304

Case: SUS304 | CR1 steel sheet

Window: PC glass

Operation

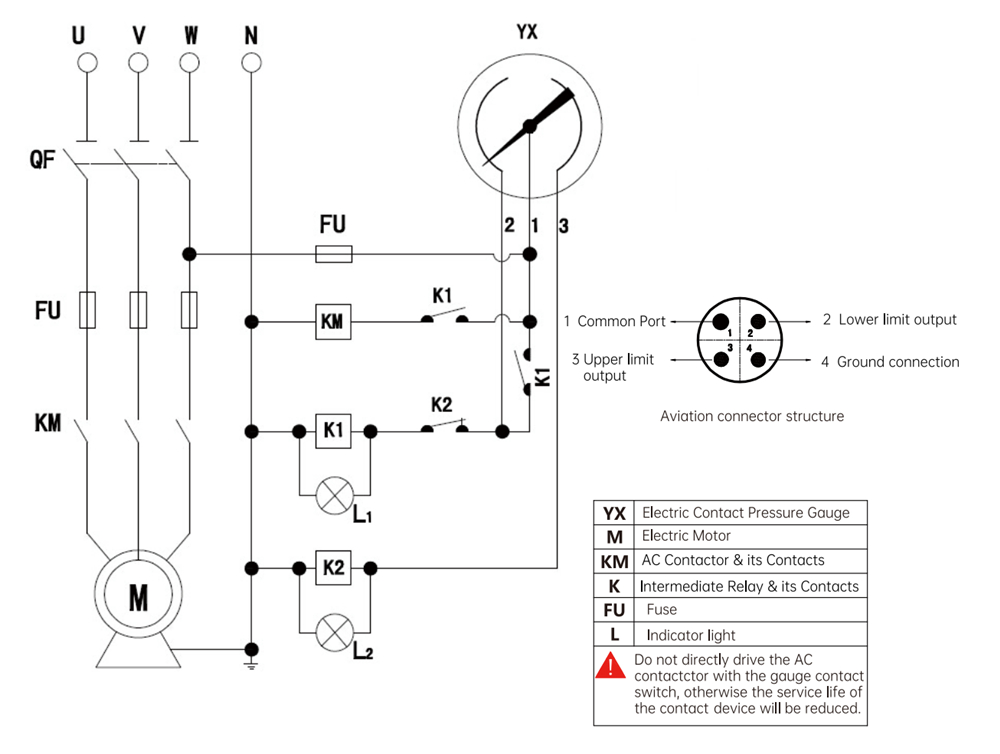

■The wiring operation should be carried out by a qualified electrician.

■When debugging or switching the control section, the control circuit should be disconnected,and the power can be turned on after the operation is completed.

■Reed switch electric contact pressure gauge must be used in a low voltage control environment within the specified technical range.Otherwise it will cause contact damage.

■Please read the instructions carefully before use.

■It is necessary to add a protective device for the pressure gauge in an environment with a sharp pressure change or vibration or pulsation.

■When installing or disassembling, don't pull the case of the gauge by hand, use a special wrench to install or disassemble.

■To measure oxygen, acetylene or other flammable gases, pressure gauge with oil prohibition signs should be used.

■The pressure gauge should be installed horizontally or vertically.

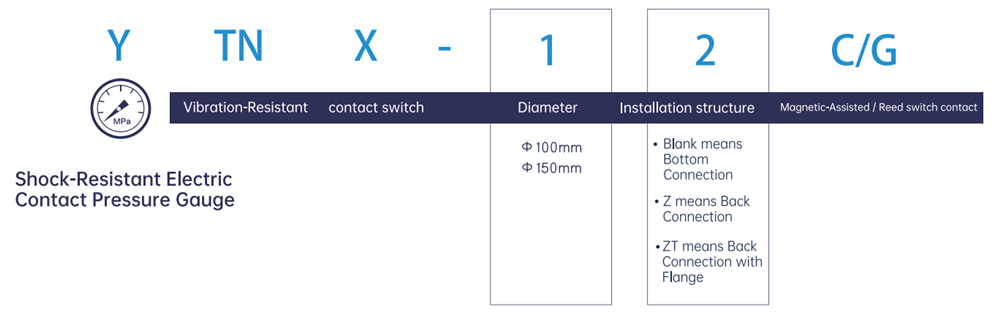

Model Code

lf you have other requirements, please confirm with our company's technical department before customizing.

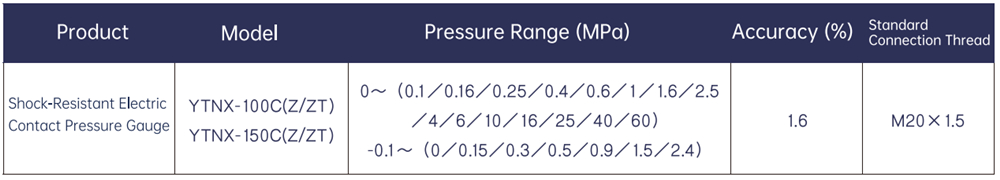

Pressure Range & Accuracy

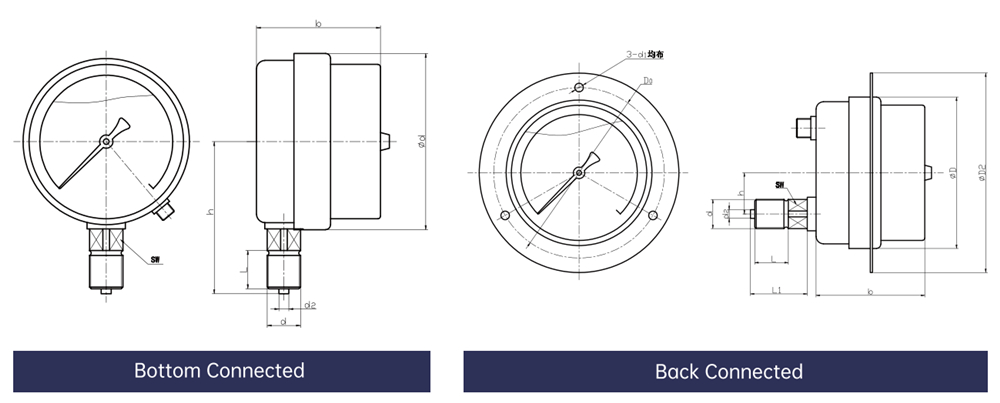

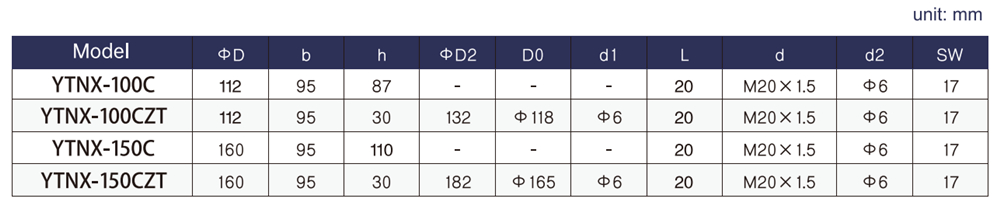

Boundary Dimension

wiring Diagram

Size

Demo Mode

★Shock-Resistant Electric Contact Pressure Gauge, Diameter φ100, Bottom Connected, Pressure Range0~1MPa, Connection Thread M20x1.5, stainless steel material.

If you can provide information such as measuring medium, installation conditions, etc., we can select the model for you more quickly and accurately.

Order Remarks

Safety Warning

For safety, please select the correct model of product. If the product is selected or used improperly, it may cause property loss or personal injury. The designer and user of the system should be fully responsible for selecting the correct product and using the product in the correct way.